2023/24 Region XI & Chapter Winner

Category: Commercial Buildings for an Existing Facility.

Submitted by, Isaac Golumbia, EIT (he/him)

Polar Engineering

PROJECT: Site-Specific Pool Dehumidifier

OWNER: Hollyburn Country Club

GROSS BUILDING AREA: 10,955 ft2

Introduction

The Hollyburn Country Club is a private facility spanning 47 acres in West Vancouver. The club was established in 1958, and provides recreational activities for members, including swimming, skating, tennis, and more. Hollyburn reached out to Polar Engineering to develop an audacious and innovative replacement for their failing pool dehumidifier, as the existing unit was at end of life and unable to meet temperature and humidity setpoints within the facility’s natatorium. As part of the design Hollyburn stressed the importance of being industry leaders by slashing the pool dehumidifiers’ natural gas use by 100% while using a low GWP refrigerant.

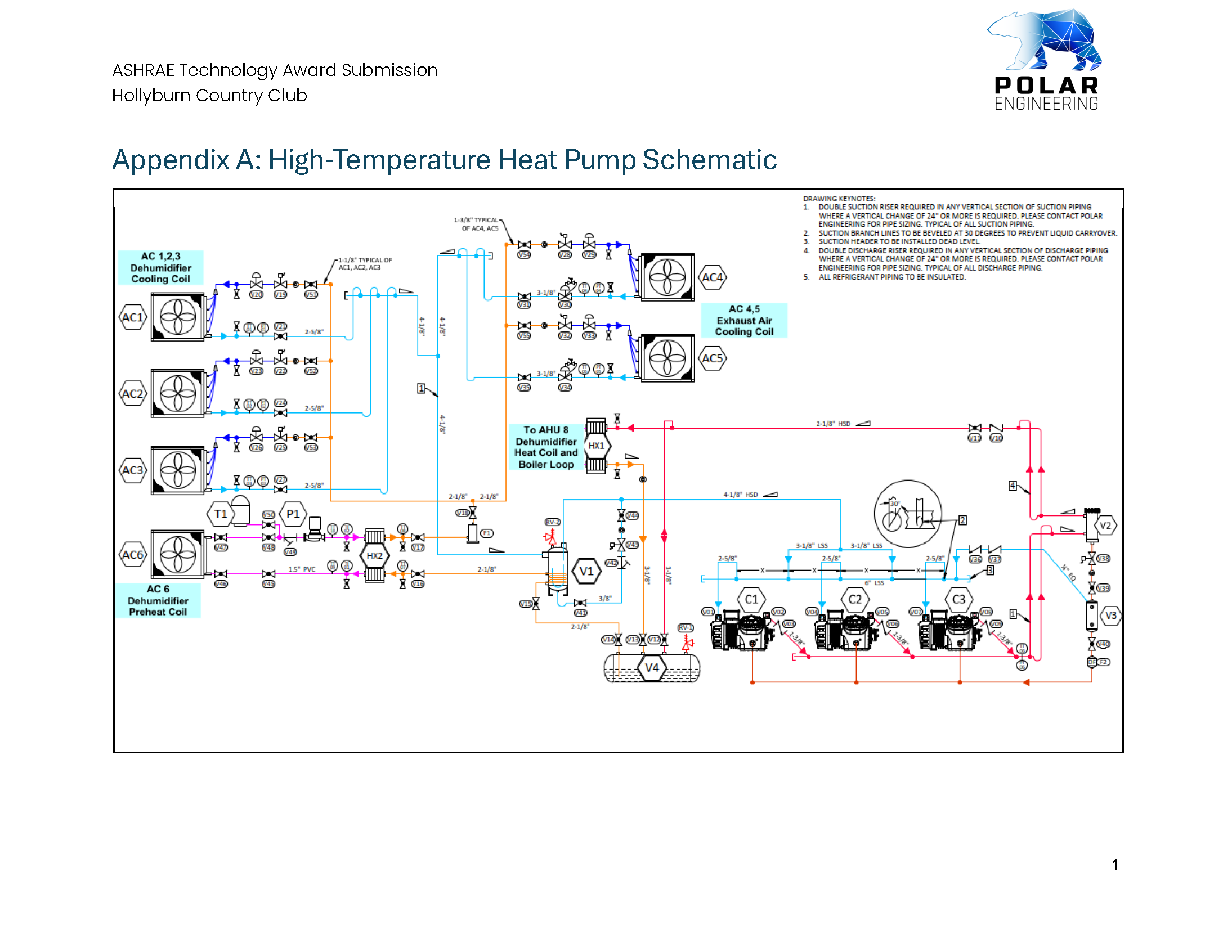

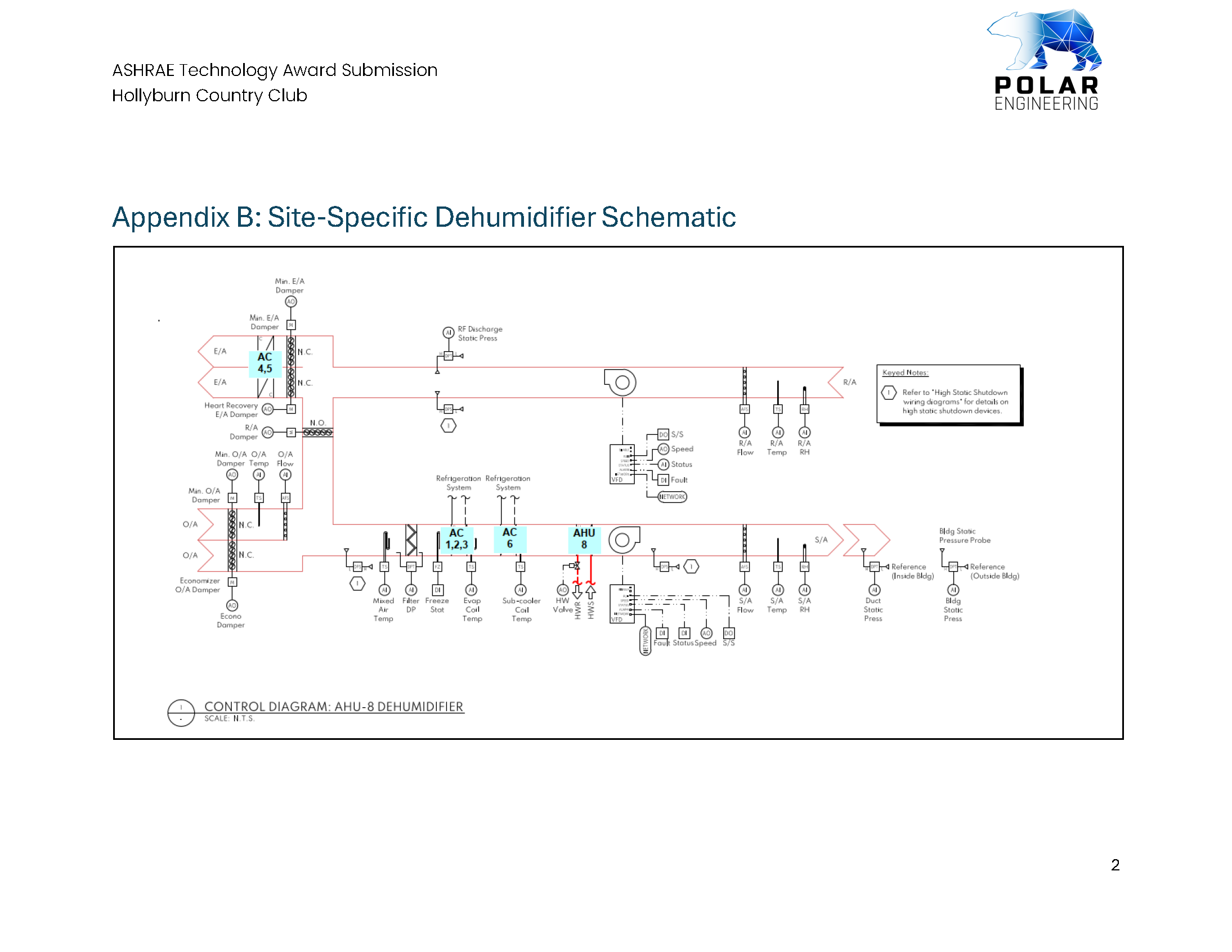

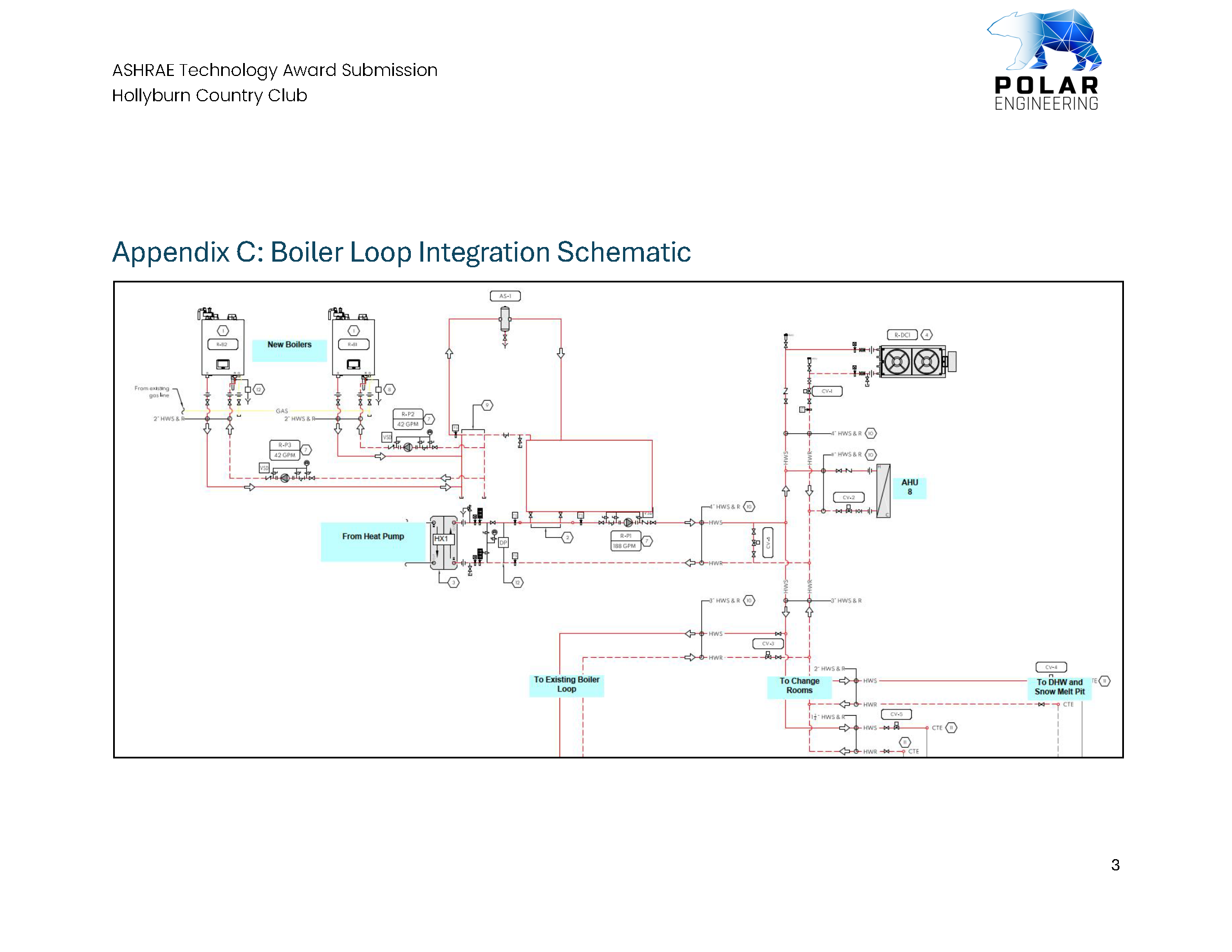

To meet the needs of the Hollyburn Country Club; Polar Engineering worked alongside First Light Energy Solutions and Fraser Valley Refrigeration to design, build, and commission one of the first high temperature, low GWP dehumidifiers in North America. The innovative design includes the integration of a low GWP high-temperature dehumidifier with the building’s 71˚ C boiler loop. The overall design allows for significant natural gas savings, resulting in emission reductions of over 6150 tCO2e over the dehumidifier’s life, and operational cost savings of $49,382 per year.

Innovation

To meet Hollyburn’s audacious design goals, the engineering team focused on several aspects of the custom refrigeration system to maximize the facility carbon reductions and operational cost savings of the dehumidifier, namely:

First, the use of Bitzer reciprocating compressors allows the heat pump’s condenser to produce leaving water temperatures up to 83˚ C, far higher than typical dehumidifiers can provide. By integrating the dehumidifier’s condenser directly with the facility’s boiler loop, recovered heat can be used to meet 100% of the dehumidifier’s air reheat load while also offsetting a large amount of the heating loads throughout the facility that would otherwise be met through the combustion of natural gas. Additionally, this dehumidifier has been designed to recover energy from both the pool return and exhaust airstreams, ensuring the dehumidifier can always operate at maximum capacity and efficiency.

Second, the dehumidifier includes an additional heat exchanger dedicated to refrigerant subcooling, a feature not often seen in dehumidifier designs. This benefits the refrigeration system in two ways. First, a significant amount of high-grade energy can be extracted from the liquid refrigerant prior to the evaporator, allowing over 60% of the air reheat load to be met with an air preheating coil. Additionally, by subcooling the refrigerant far beyond its saturation point, the refrigerant quality at the inlet of the evaporator is reduced by over 30%, greatly increasing the system’s cooling capacity and energy efficiency. Overall, the subcooler increases the cooling and heating EER of the heat pump by 43% and 29%, respectively.

Lastly, the refrigeration system utilizes R-513a as a high temperature low-GWP refrigerant.

Energy Efficiency

Energy and emissions savings were emphasized highly in this design. The dehumidifier has a cooling efficiency of 9.83 (EER) and a heating efficiency of 13.25 at design conditions of a suction temperature of 3˚ C and condensing temperature of 76˚ C. The dehumidifier has been optimized to use the dehumidification of the pool to offset more than 6000 GJ of natural gas heating per year. This is done by using the control system to shift the dehumidifier between active (cooling the process airstream) and energy recovery (cooling the pool exhausted air) dehumidification to always maximize carbon reductions. This has yielded facility emissions savings of over 300 tCO2e per annum.

Indoor Air Quality

Hollyburn’s key metric was the improvement of the indoor air quality and thermal comfort for facility occupants, while also ensuring energy savings. Therefore, the dehumidifier was designed with Demand Control Ventilation (DCV) to minimize the ODA conditioning requirements while also meeting the ASHRAE 62.1 standard air change over rate of 4.5 ACH. To ensure thermal comfort the onboard Delta controls balances active dehumidification, ODA, and supply air heating to maintain the pool at 27.5˚ C and 55% RH.

Operation & Maintenance

Polar prioritized ease of operation and maintenance in several ways. Firstly, safety was ensured by selecting a nonflammable, nontoxic, and high temperature A1 refrigeration (R513a). Secondly, ease of ongoing maintenance was prioritized by constructing the custom dehumidifier with industry standard components which can be purchased off the shelf. Thirdly, Polar ensured ease of ongoing maintenance by installing all equipment in a new easily accessed custom built mechanical room. Finally, operational savings of $49,382 per year were achieved by integrating dehumidifier energy recovery with the building’s 71˚ C boiler loop.

Cost Effectiveness

When compared to an off the shelf dehumidifier the Hollyburn custom-made dehumidifier and heat pump came at a cost premium of $420,000. To offset these costs Polar first worked with First Light Energy to obtain a $500,000 carbon reduction grant and integrated the dehumidifier with the facility’s boiler loop to reduce the total natural gas costs by $49,382 per year. Therefore, resulting simple payback period of less than one year.

Environmental Impact

The innovative dehumidifier design supplies high quality heat at 78˚ C, allowing up to 1,220,000 btu/hr of recovered heat to be used to offset natural gas loads and reducing Hollyburn’s GHG emissions by more than 300 tons per year.

Furthermore, to further reduce the dehumidifier’s lifetime carbon emissions Polar engineered the heat pump to use the low GWP refrigerant R-513a (GWP of 573 and 0 ODP) instead of the industry started R410a (GWP of 2088 and 0 ODP). Considering a global average refrigerant leak rate of 10% per year the installed R-513a refrigeration system has a 73% reduction in lifetime GHG emissions when compared to R410a.

Taking both these items into account, Polar is proud to affirm that the Hollyburn pool dehumidifier will reduce the facility’s carbon emissions by more than 6150 tCO2e over the dehumidifier’s life.